The sun, a boundless source of energy, has captivated humanity for millennia. Now, more than ever, we're harnessing its power on an unprecedented scale, with monocrystalline solar panels at the forefront of this revolution. These sleek, black panels are not just aesthetically pleasing; they represent a pinnacle of solar technology, boasting higher efficiency and longer lifespans compared to their polycrystalline counterparts. Their superior performance stems from a unique manufacturing process that results in a highly pure silicon structure, maximizing the absorption of sunlight and conversion to electricity.

This article will delve deep into the intricacies of monocrystalline solar panels, exploring their production, advantages, and applications. We will take you through a step-by-step process, from silicon ingot creation to the final panel assembly, revealing the science behind their remarkable energy-generating capabilities. Prepare to uncover the secrets of these high-performing solar powerhouses and understand why they are the preferred choice for many residential and commercial installations.

Preparation and Safety Guidelines

- Solar cell

- Multimeter

- Power supply

- Camera (with removable filter)

- LEDs

- Solar modules

- Inverter

- Charge controller

- Battery

- Never touch the solar panel's surface while it's energized. High voltage can cause serious injury or death.

- Always disconnect the solar panel from the electrical system before cleaning or performing any maintenance. Failure to do so could result in electric shock.

- Use appropriate personal protective equipment (PPE), including gloves and eye protection, when handling solar panels and associated wiring.

Step-by-Step Instructions

The Fundamentals of Solar Power

- Sunlight (or artificial light) generates voltage in a solar cell.

- Photons knock electrons out of the silicon, creating electron-hole pairs. Electrons flow through a wire to the positive electrode, creating a current.

The Fundamentals of Solar Power Monocrystalline Solar Cell Construction

- A metal conductive plate (positive electrode), thin silicon layer (semiconductor with Boron and Phosphorus layers forming the PN junction), anti-reflective coating, metal grid (negative electrode with fingers and bus bars), and a protective glass layer.

Monocrystalline Solar Cell Construction From Cell to Module

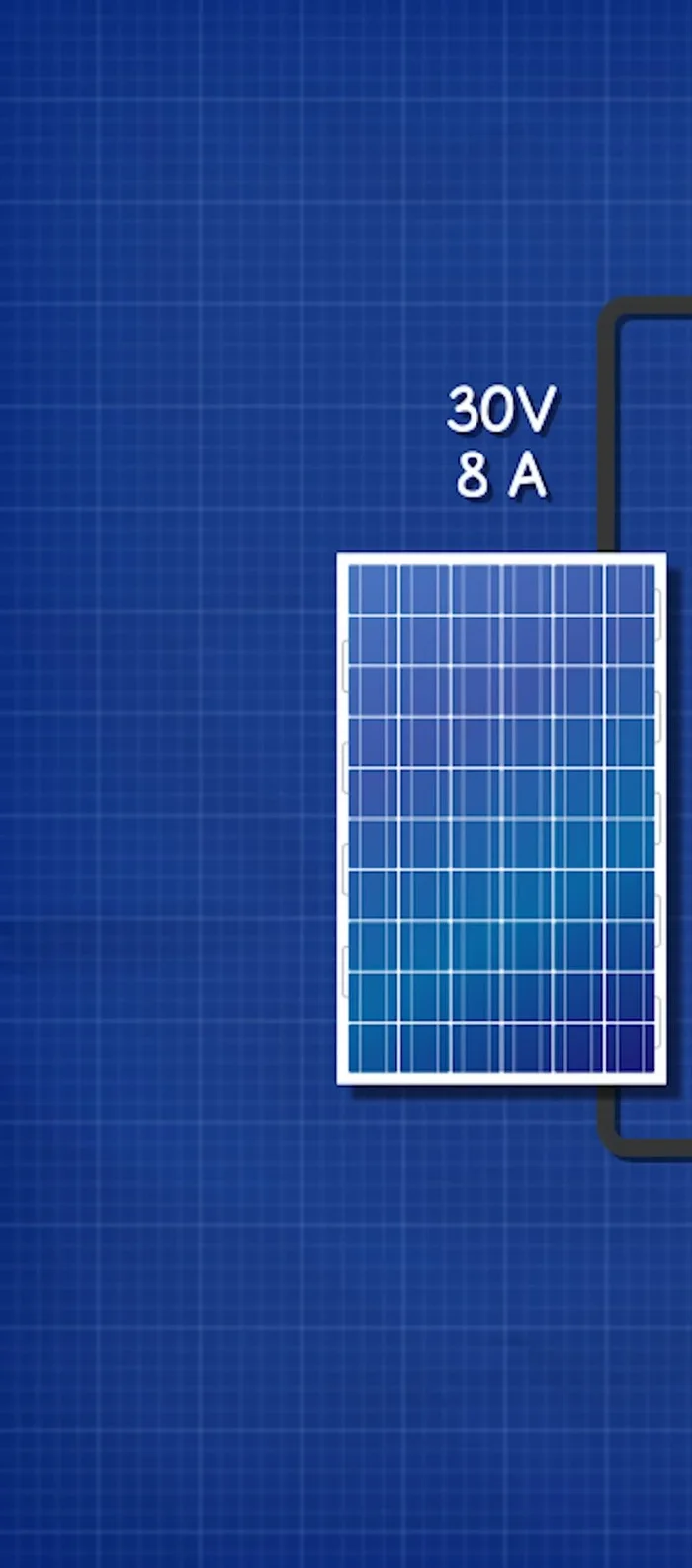

- Multiple solar cells are connected in series to increase voltage and then multiple strings of modules are connected.

From Cell to Module System Design and Integration

- Modules connect to a charge controller and inverter to manage voltage and current, and convert DC to AC for household use.

System Design and Integration Grid-Tied vs. Off-Grid Systems

- Solar systems can be standalone or grid-connected, selling excess energy back to the grid.

Grid-Tied vs. Off-Grid Systems

Read more: Harnessing Solar Power: A Green Energy Solution

Tips

- Optimal Panel Orientation: Angle solar panels perpendicular to the sun for maximum efficiency. Software like PVsyst can help optimize placement and angle.

- Consider Shade Analysis: Remove overshadowed modules to maximize energy capture.